- About Aginode

- Data Networks

- Telecom Infrastructure

- Products

-

Resources

- Resources

- Documentation

- Blog

-

Case Studies

- Overview

- Innoasis development in Norway

- Eemsdelta Campus

- Hotelschool The Hague

- Emergency covid hospital, Hong Kong

- Société du Grand Paris

- Centrin Datacentres

- Airbus

- Athens Historic City Hall

- Pinewood Studios

- Goethe University Frankfurt

- Denmark New University Hospital

- University of Toulouse

- CHM Maubeuge: a model for future-ready hospitals

- Webinars

- Software Tools

- Warranty

- Newsroom

- Search

- Contact us

- Compare

- Sign in

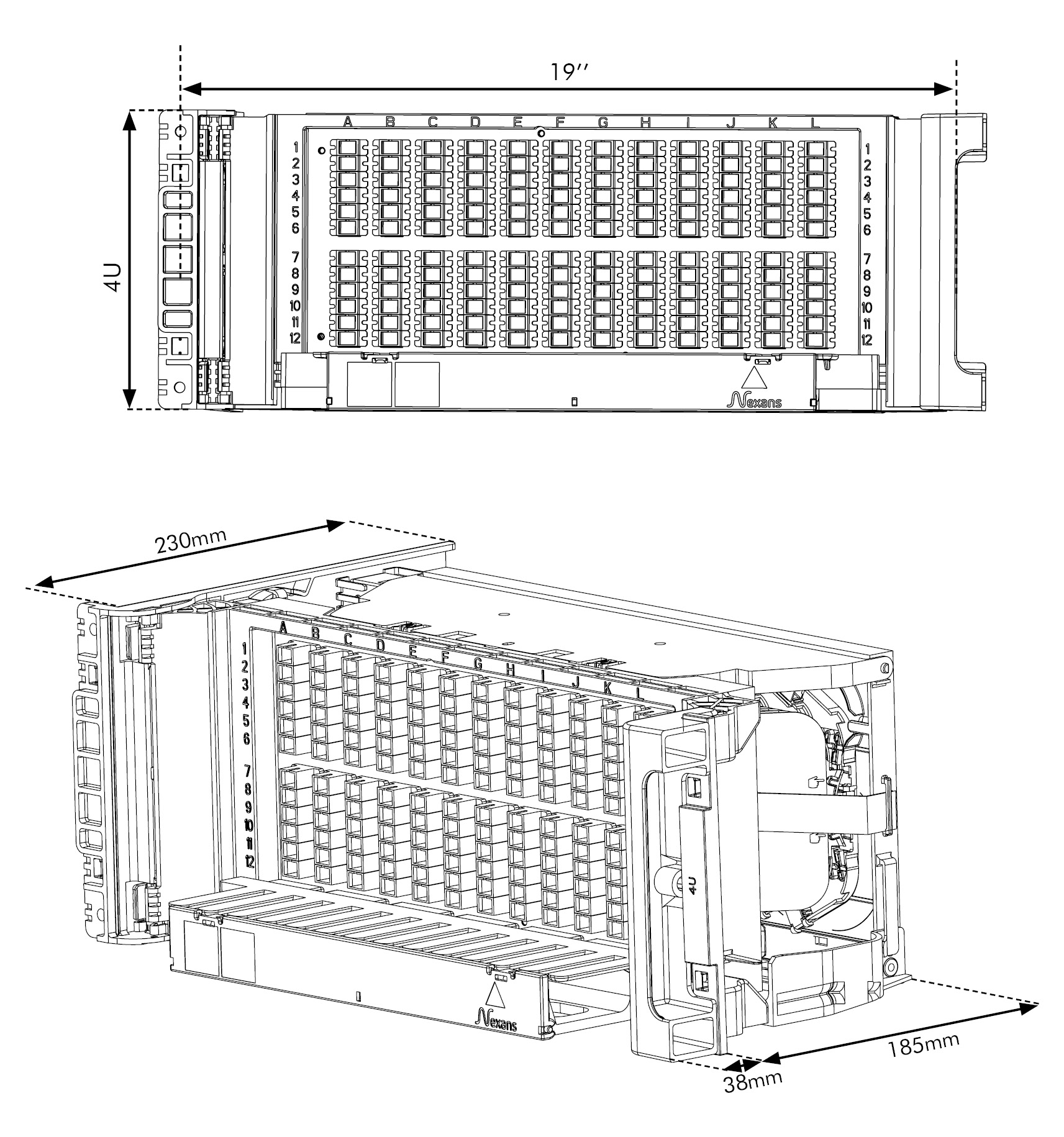

XPLORER™ - Patching 4U

XPLORER™ - Patching 4U

XPLORERTM

- Swiveling 4U module for patching

- Up to 144 SC and LC connections

- 19'' racks and cabinets

- Manufactured with fibre reinforced composite

Description

Description

Standards

-

InternationalIEC 61753-1

The swivelling 4U module pivotes around the axis of the fixed chassis. It is locked on the other side. The depth of the panels is reduced to 230mm based on the pivoting concept.

The rear of the 4U panel rotates open to have easy access to the splice cassettes. After splicing the rear is closed again so that the splice cassettes are protected by a cover.

The panels are symmetrical and can be configured as left or right swilling modules.

Material and usage characteristics

The panels are made of fibre reinforced composite. This makes the panels more robust compared to traditional metal panels.

The panels are resistant against corrosion, Fungi, UV and the most important aggressive chemicals.

The reduced weight of the panel of around 3,2kg allows the panel to be installed by a single technician.

Density and adaptors

Different connector types and densities are supported. The maximum density is 144 fibre connections for SC and LC connectivity. The SC adaptors have translucent dust caps to allow for visual fault locator so that for instance subscribers and optical channels can be easily identified. The power reduction of the translucent dust caps is 3.5 dB. The LC adaptors have White dust caps that block the laser light.

Fixing of the breakouts

The panel is supplied with 2 fixing kits for break-outs with tie wraps:

- break-out fixed in the fixed chassis

- break-outs fixed in the swivelling module

The overlengths of the break-out legs can be arranged into management rings.

Patching

The adaptors are organized in 12 columns of each 12 adaptors. Letters from “A” to “L” identify the vertical columns. The horizontal adaptor rows are numbered from “1” to “12”.

The patch cords are guided per column to the bottom of the panel. An integrated patch cord guide routes the cords to the pivoting axis.

The panel is delivered with a spool kit. It is fixed on the side of the rack with metal cage nuts. The spool kit manages the cords nicely in the cabinet.

Panel fixing

The panels are fixed inside racks with 9,5mm square slots with sockets and pawns that are toolless installed from the front. The fixed chassis and the lock are fixed on the front rail of the cabinets and for enhanced stability during pivoting the fixed chassis on a support rear rail.

Metal cage nuts for 8,3mm and 9,5mm square slots are also supplied.

Green solution

Panels based on fibre reinforced composite have a significant lower environmental impact, especially during production.

The packaging and the protections inside the box are made of cardboard only. This results in a reduced volume of waste and easy treatment.

Available products XPLORER™ 4U - Patching

| SAP-number | Description |

| 13200109 | XPLORER™ Patching Grade B 4U 144xSC/APC |

| 13200110 | XPLORER™ Patching Grade B 4U 144xLC/APC |

Dimensions XPLORER™ 4U

Characteristics

Characteristics

Construction characteristics

Construction characteristics

Dimensional characteristics

Dimensional characteristics

Usage characteristics

Usage characteristics

Resources

Resources

Documentation

Selling & delivery Information

Delivery units - 1U : 72 units per palet - 3U and 4U : 20 units per palet

Our websites

Select your country to find our products and solutions

-

Africa

- Africa

- Ghana

- Ivory Coast

- Morocco

- North West Africa

- Americas

- Asia

- Europe

- Oceania